Sandwich mounts are an excellent way to reduce vibration and shock, among many other benefits. They are used in all sorts of industries and for many different applications.

Sandwich mounts are an excellent way to reduce vibration and shock, among many other benefits. They are used in all sorts of industries and for many different applications.

Excessive vibration can cause major damage to both machinery and operators. Sandwich mounts are one of the best solutions to vibration and other common problems.

At RPM Industrial Rubber Parts, we offer many kinds of sandwich mounts as well as other standard rubber parts. Visit our website to learn more.

Read on to learn what a sandwich mount is and what it is used for.

Benefits of Sandwich Mounts

There are many benefits to using high-quality sandwich mounts, which include:

- High carrying capacity: many sandwich mounts are manufactured to take on high loads. Some can handle up to 7,000 lbs in compression static loads.

- Easy to install: the minimalistic design of these parts makes them easy to install.

- Maintenance-free: because these parts are made out of rubber, they require no maintenance.

- High compressive strength: more compression means more energy control, vibration damping, and shock reduction capabilities.

- Excellent bond: because sandwich mounts are metal to rubber bonded parts, they are thoroughly bonded for maximum durability.

Sandwich Mount Design

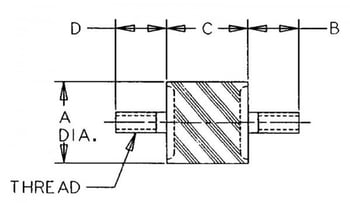

There are a few designs for sandwich mounts that will best suit specific applications. Most often, a sandwich mount consists of a rubber cylinder with a metal plate and stud on both ends. Some sandwich mounts may have one metal plate, or none at all, while some will have one stud or none at all. Again, it depends on the specific mount and its intended use.

Take a look at the different kinds of sandwich mounts:

- Bobbin sandwich mounts

- Large shear mounts

- Square pad mounts

- LORD Flex-Bolt™ Sandwich Mounts

Some sandwich mounts look completely different, although the concept stays the same. For example, large shear mounts have two square metal plates with a cylindrical rubber piece in the middle. The metal plates do not have any studs. Instead, they have multiple holes for the studs to go once installed.

Access Selecting a Vibration Shock Isolator Guide

To learn more about vibration isolation mount design and which one you need, read our free guide.

Sandwich Mount Function

The main function of a sandwich mount is to reduce vibration and shock. It does this through the compressive design and vibration damping rubber.

Imagine a static piece of machinery with excessive vibration. If that machine is placed on a shop floor or warehouse, the machine, product, and operator could face damage from the vibration. Now, what if you tightly mounted a piece of rubber to both the machine and the floor? The vibration would cease, or at least diminish.

This is how a sandwich mount works. It compresses the two pieces together and absorbs the vibration into the rubber.

Sandwich mounts also act as buffers in spring mounts and are used in sensitive equipment where even a small amount of vibration can have a substantial impact. Overall, the function of a sandwich mount is vital to the performance of machinery and equipment.

Materials of Sandwich Mounts

There are a few materials that are used in sandwich mounts. The metal studs and plates are typically made of steel, aluminum, or stainless steel. These provide the highest strength at the lowest cost.

The rubber materials, on the other hand, can get complicated. Choose the right rubber polymer and you end up with a strong, anti-vibration mount. Choose the wrong rubber polymer and the sandwich mount may not work at all.

These are some of the rubber materials used in sandwich mounts:

- Natural rubber: this is the most common rubber polymer. It has excellent vibration reduction and fatigue resistance. However, it is not as resistant to extreme temperatures as other polymers.

- Silicone: while regularly produced silicone has low tear resistance, sandwich mount manufacturer LORD produces its own silicone. This silicone is of high quality with excellent vibration and temperature resistance.

- Neoprene: another common rubber polymer used in sandwich mounts, neoprene has high tensile strength and abrasion resistance. Although it is sensitive to fluids such as oil and chemicals, it is still used in sandwich mounts.

Although there are a few more polymers used in sandwich mounts, these are the most common.

Quality Custom and Standard Rubber Parts Service

-2.png?width=400&name=Sandwich%20Mounts%20Parker%20LORD%20(1)-2.png) Sandwich mounts are not the only important rubber part involved in the complicated workings of machines and equipment. It would probably take hours just to list out all of the rubber components used by a typical OEM for fleet and working vehicles. This is why it is important to have a rubber parts service dedicated to customer service and quality.

Sandwich mounts are not the only important rubber part involved in the complicated workings of machines and equipment. It would probably take hours just to list out all of the rubber components used by a typical OEM for fleet and working vehicles. This is why it is important to have a rubber parts service dedicated to customer service and quality.

RPM Industrial Rubber Parts know the value that sandwich mounts provide. That’s why we never cut corners during manufacturing. We take the time to fully prepare the metal for bonding and thoroughly test the mounts when the bonding process is finished. And, before you purchase the mounts you need, our team completes an in-depth analysis to determine which mount is best for your specific application.

At RPM Industrial Rubber Parts, you can expect all of this and more. We offer standard rubber parts such as sandwich mounts, as well as custom rubber parts. Our team of highly skilled engineers is ready to help you pick the parts you need and design the ones you can’t seem to find.

To get in contact with our team, give us a call at (888) 842-5668 or contact us online.